RS232/RS485 Communication Interface Motor Cogging Force Analysis

System for Accurate Results

Product Description:

Precision Motive’s Cogging Test System is a cutting-edge system

that can independently control and measure Detent Torque, Cogging

Torque and Friction Torque. This system offers a host of advanced

features, including a precision geared motor, a JT Series Torque

Sensor that integrates with a 5 000 pulses encoder, and built-in

security clutches for JT101 to JT303 to prevent overload when not

in use.

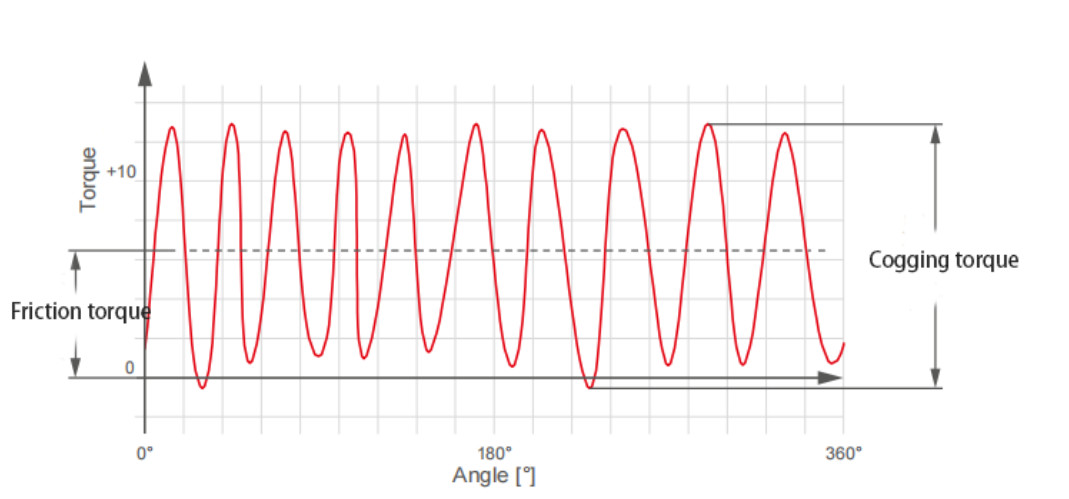

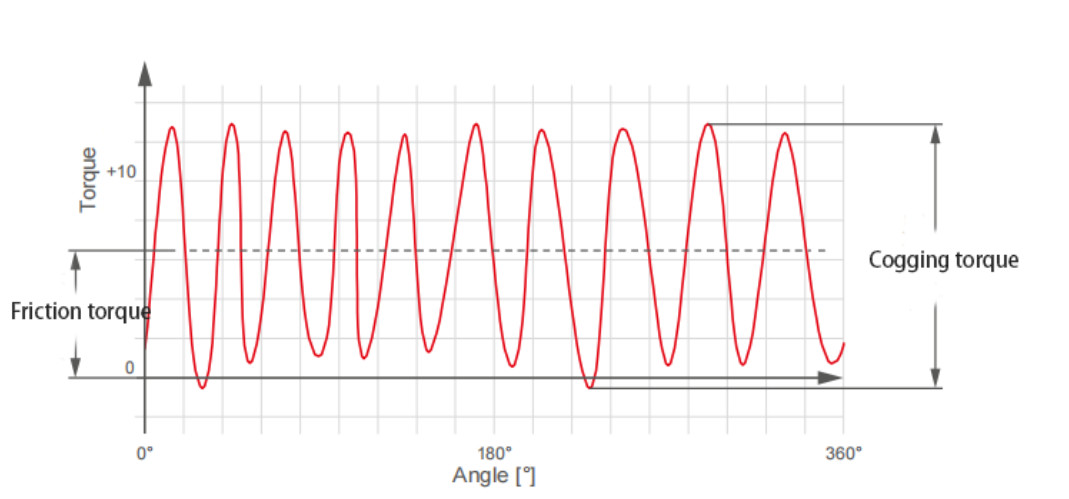

The Cogging Test System operates by driving the Motor Under Test

(MUT) at a low speed (1 … 10 rpm) through the geared motor while

acquiring its cogging torque in relation to angle position. The

torque measurement range covers up to 2 N∙m (depending on the

selected torque sensor) and offers an accuracy of ± 0.1 mN∙m (for

JT 101 – 10 mN∙m and JT 303 – 3000 mN∙m).

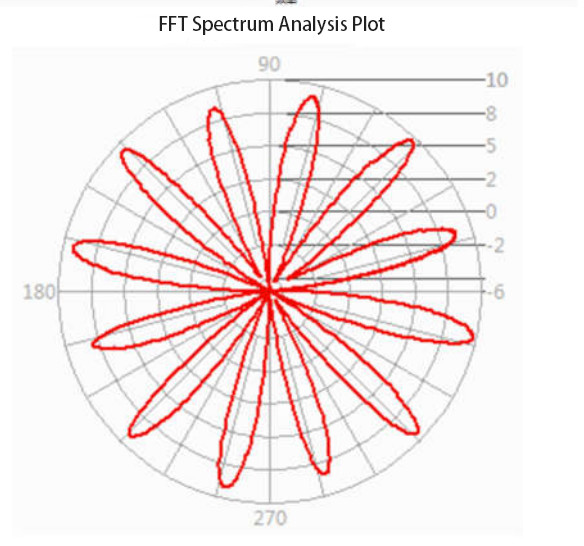

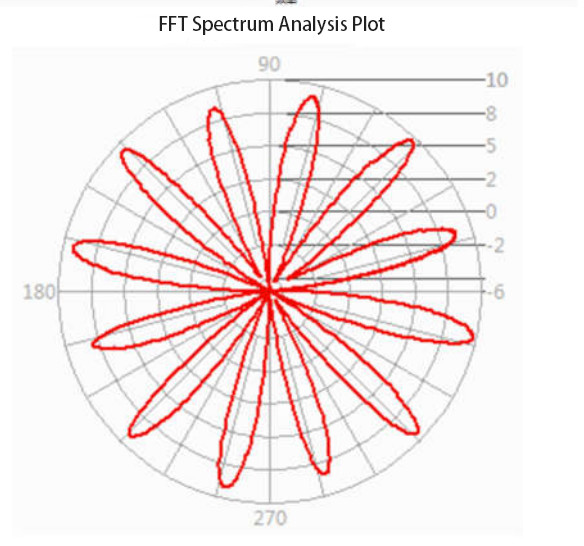

The system’s software is designed to provide greater control over

its functions. It is capable of executing system controls,

displaying acquired data and carrying out accurate peak-to-peak

measurement of cogging torque. It also offers display options for

X-Y or polar graphs as well as FFT analysis. Additionally, it

allows for the storage of measured data and provides up to

five-graph comparison of performance data. A cursor is also

included in the software, which allows for accurate readings to be

taken from the measurement points. Finally, the software can save

measured parameters as a text file TXT.

For enhanced accuracy and function control, the software includes a

zero offset adjustment feature. This feature checks the

transducer's signal over a complete turn, even when the test sample

MUT is not connected to the system.

Technical Parameters:

Mechanical Characteristics

| MODEL | JT-500 | JT-101 | JT-501 | JT-102 | JT-302 | JT-502 | JT-103 | JT-303 |

|---|

| Rated torque (RT) | 5 mN.m | 10 mN.m | 50 mN·m | 100 mN·m | 300 mN·m | 500 mN·m | 1 N·m | 3 N·m |

| Accuracy | 1% of RT | 0.5% of RT | 0.2% of RT | 0.2% of RT | 0.2% of RT | 0.2% of RT | 0.2% of RT | 0.2% of RT |

Measurement Characteristics

- Speed range: 1 to 10 rpm (other speed ranges can be customized)

- Angle detection: 0.018° (5000 pulses/rotation)

- Test direction: clockwise & counterclockwise

Environmental Requirements

- Working temperature range: +10℃ to +45℃

- Storage temperature range: 0℃ to +70℃

- The effect of temperature on zero position: 0.01% / ℃

- Protection level: IP 42

Electrical Characteristics

- Power requirement: 220-240 VAC/50 Hz (max. 1 A)

- Communication port: USB-B 2.0

- The connecting cable includes: a 2m USB cable

The above text describes the mechanical, measurement,

environmental, and electrical characteristics of different models

of torque sensors. These sensors are capable of measuring torque in

various ranges, with varying degrees of accuracy, and can also

detect the speed and direction of rotation. The working and storage

temperature ranges, as well as the effect of temperature on zero

position, are also specified. These sensors have a protection

rating of IP 42. They require a power supply of 220-240 VAC/50 Hz

and can be connected through a USB-B 2.0 port using a 2m cable. The

speed range of these sensors can be customized based on the

requirements of the user.

Applications:

One of the main applications of the JT cogging test system is in

the production of electric motors and generators. Manufacturers can

use the system to test the cogging torque of their products and

identify any issues that may be affecting performance. The system's

accuracy of +/- 0.5% ensures that measurements are precise and

reliable, helping manufacturers to improve the quality of their

products.

The JT cogging test system is also useful in research and

development. Engineers can use the system to test the cogging

torque of different motor designs and identify which designs are

most efficient. This can help to improve the overall performance of

motors and generators, reducing energy consumption and improving

productivity.

The operating temperature range of 10°C - 40°C makes the JT cogging

test system suitable for use in a wide range of environments. It

can be used in factories, research labs, and testing facilities

without the need for additional climate control systems.

Additionally, the system's power supply of AC 220V, 50Hz ensures

that it can be used in most locations around the world.

When not in use, the JT cogging test system can be stored at

temperatures ranging from -20°C to 40°C. This ensures that the

system remains in good condition and is ready for use whenever it

is needed.

In summary, the Precision Motive JT cogging rotation test system is

a magnetic cogging detection system that is ideal for use in the

production and research of motors and generators. Its accuracy,

lightweight design, and wide operating temperature range make it a

versatile tool that can be used in a variety of environments.

Whether you are a manufacturer looking to improve the efficiency of

your products or an engineer looking to develop better motor

designs, the JT cogging test system is an essential tool to have in

your arsenal.

Support and Services:

The Cogging Test System is a high-precision measurement system

designed to detect the cogging torque of electric motors and

generators. It includes a powerful software package that provides

the user with real-time measurements and analysis tools. Our

technical support team is available to assist with installation,

calibration, and troubleshooting of the system. We offer on-site

training and maintenance services to ensure optimal performance and

longevity of the product. Additionally, we provide software updates

and enhancements to continuously improve the functionality of the

system.

Packing and Shipping:

Product Packaging:

- 1 Cogging Test System unit

- 1 power cord

- 1 USB cable

- 1 user manual

Shipping:

- Shipping method: UPS Ground

- Shipping cost: $25

- Expected delivery time: 3-5 business days

FAQ:

Q: What is the brand name of the Cogging Test System?

A: The brand name of the Cogging Test System is Precision Motive .

Q: What is the model number of the Cogging Test System?

A: The model number of the Cogging Test System is JT .

Q: Where is the Cogging Test System produced?

A: The Cogging Test System is produced in China .

Q: What is the purpose of the Cogging Test System?

A: The Cogging Test System is designed to measure the cogging

torque of motors and generators to ensure their quality and

reliability.

Q: What kind of motors and generators can be tested with the

Cogging Test System?

A: The Cogging Test System can be used to test various types of

motors and generators, including permanent magnet motors, brushless

DC motors, and synchronous generators.